How are thin-film solar modules manufactured

and how do TSMC CIGS modules work?

The central concept common to all thin-film modules is the use of a single, very thin deposited layer of semiconductor material in order to avoid the high costs of the raw materials and energy required to produce high-purity silicon wafers. A variety of semiconductor materials are used to make thin-film modules – those in commercial production include: amorphous silicon (a-Si), micromorph silicon (mSi), cadmium telluride (CdTe) and compounds made of copper, indium, gallium and selenium (CIGS).

Unlike typical crystalline silicon module production, producing thin-film modules involves depositing thin layers of semiconductor material on a surface made of glass, metal or plastic at 250–500°C (according to the type of material), whereby only about a tenth of the semiconductor material used in silicon wafers is required and significantly less energy needed.

As a result, the production process only has one step, making the cells, because the cells don’t have to be assembled individually, placed in an array and then interconnected for thin-film modules. Rather, they’re an intrinsic part of the module’s layer structure.

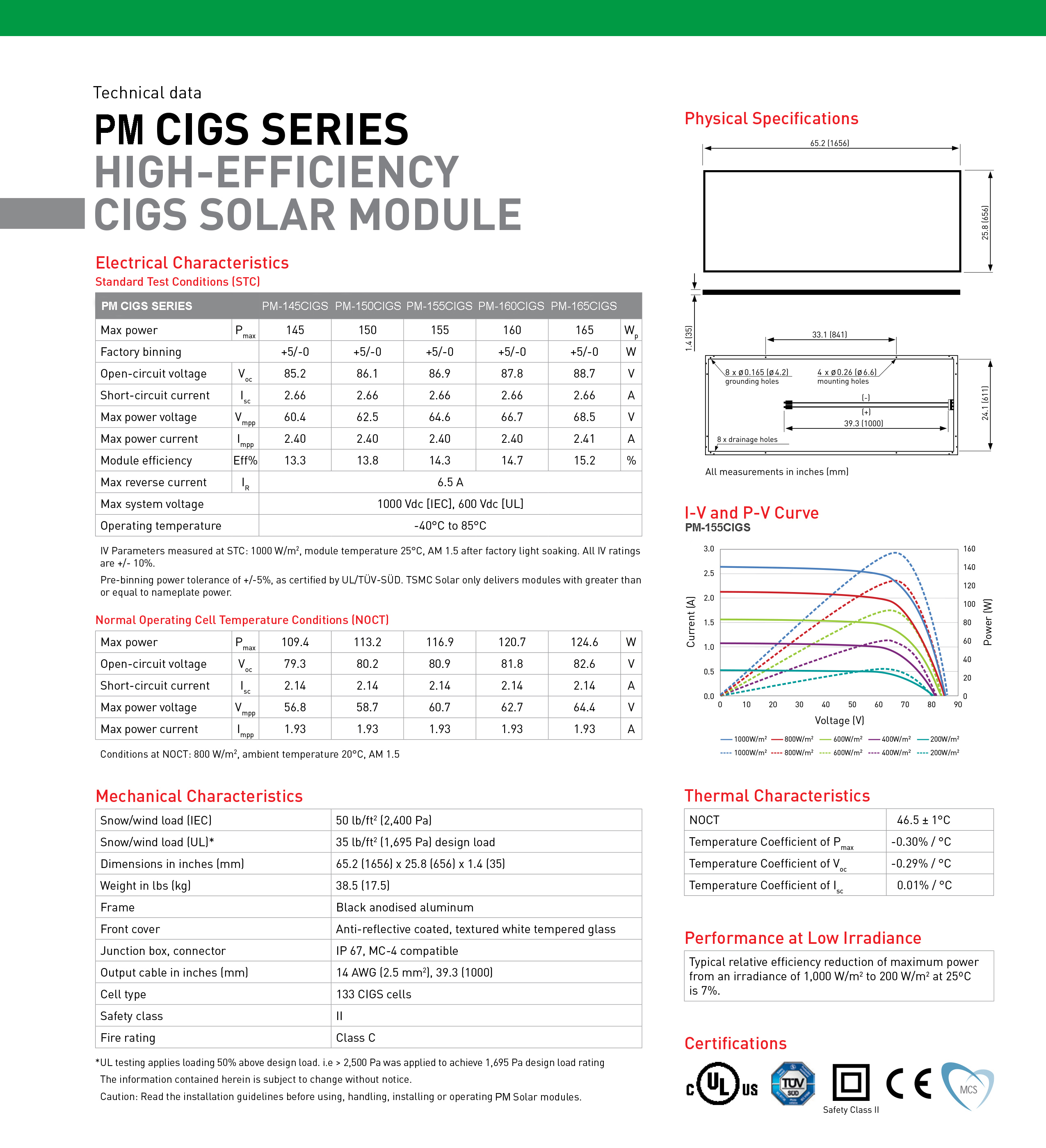

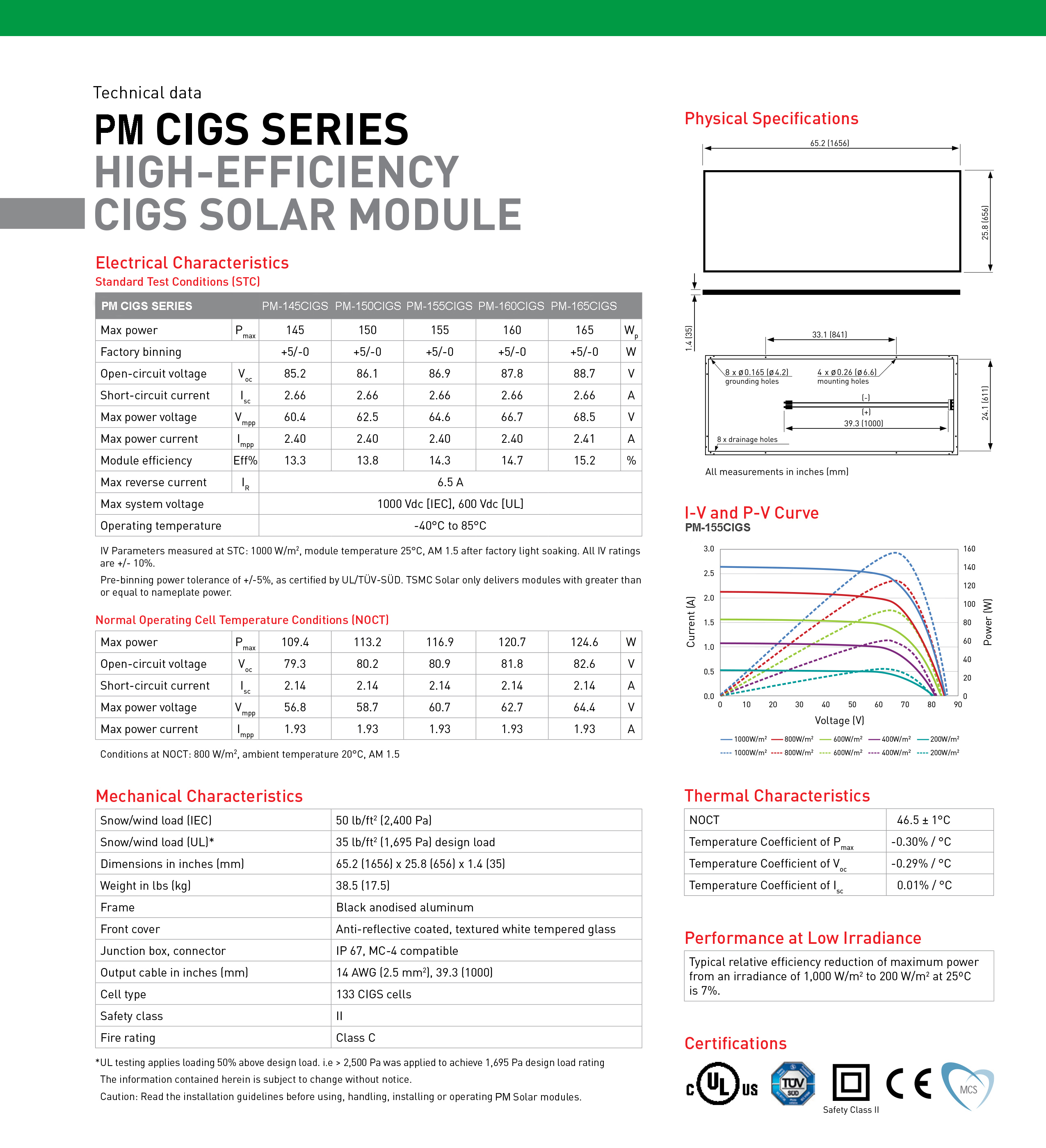

In the past, the efficiency level of thin-film modules lay noticeably below that of the crystalline modules at 6–9% – too low for mass market adoption because the amount of energy produced on a specific rooftop or in an open space was significantly lower than the value achieved by the crystalline modules.

Modern thin-film modules, particularly those with CIGS technology, achieve significantly higher module efficiency levels of up to 15% or more – comparable efficiency to crystalline silicon modules. TSMC Solar R&D prototypes have already well exceeded 17%, and weʼre confident this technology can also deliver efficiency levels of up to 17% in commercial production within a few years.

Regardless of the efficiency level, CIGS thin-film modules can also produce more energy even when the competing module’s power rating is the same due to CIGS’ good low irradiance performance. That is particularly valuable if it’s partly cloudy or if there’s diffuse or low light – conditions often experienced in regions with seasonal solar resource variations.

TSMC Solar’s advanced CIGS process enables us to deliver the potential of CIGS while maintaining manufacturing efficiency and flexibility to continuously advance our technology and product. Our process uses sputtering to achieve low costs and flexibility in the deposition of the complex films required to produce high-quality CIGS modules. Advantages include uniformity and controllability of deposition, elimination of contaminants and scalability to large module sizes. Sputtering is a widely used technology in which TSMC has deep expertise through its 25 years of semiconductor manufacturing experience.